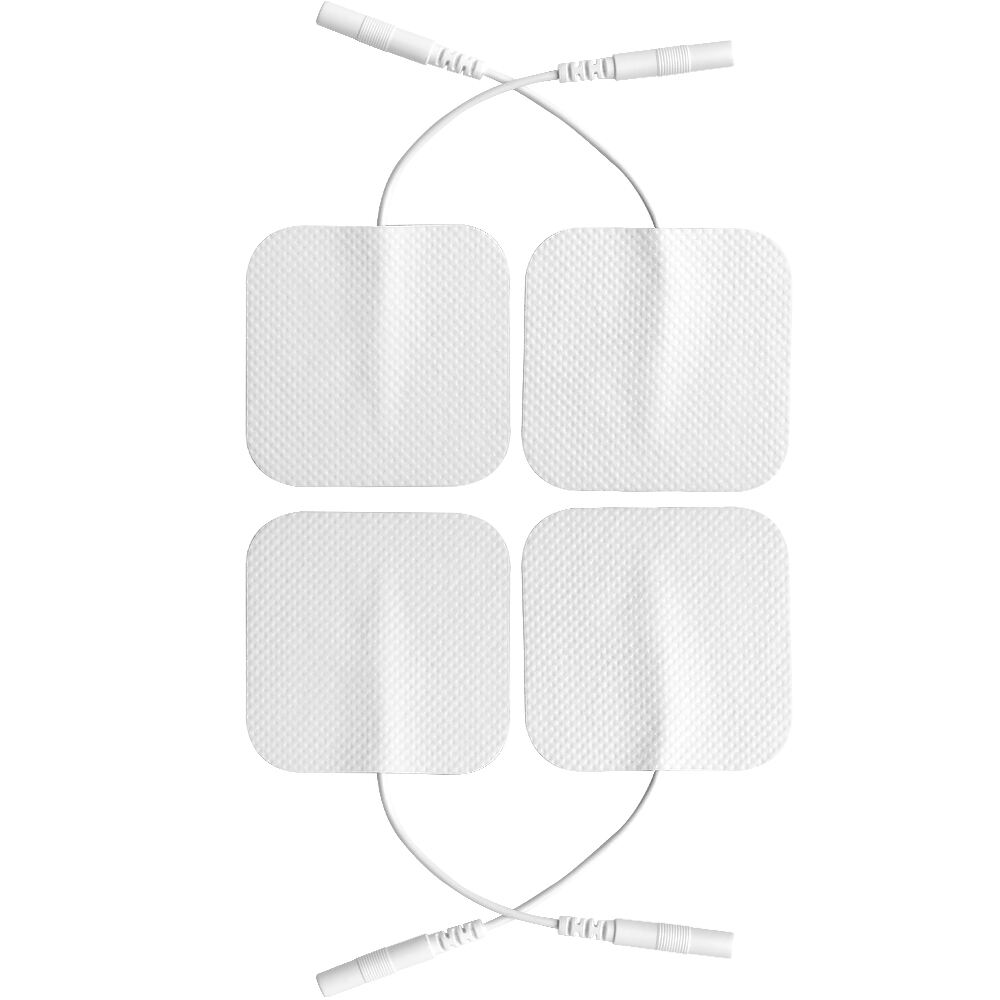

tens electrodes manufacturer

A tens electrodes manufacturer specializes in producing high-quality, medical-grade electrodes designed for Transcutaneous Electrical Nerve Stimulation (TENS) therapy. These manufacturers employ advanced production techniques and maintain strict quality control measures to create reliable, skin-friendly electrodes that effectively transmit electrical impulses for pain management and muscle stimulation. The manufacturing process involves sophisticated automation systems and precise material selection, including conductive materials and medical-grade adhesives. Modern tens electrodes manufacturers integrate innovative features such as extended durability, enhanced conductivity, and hypoallergenic properties into their products. They typically offer various electrode sizes and shapes to accommodate different treatment areas and patient needs. The production facilities maintain ISO certification and FDA compliance, ensuring consistent quality and safety standards. These manufacturers also invest in research and development to improve electrode performance, focusing on aspects like adhesive longevity, signal transmission efficiency, and user comfort. They often provide custom solutions for healthcare providers and medical device companies, including private labeling options and specialized electrode designs for specific therapeutic applications.